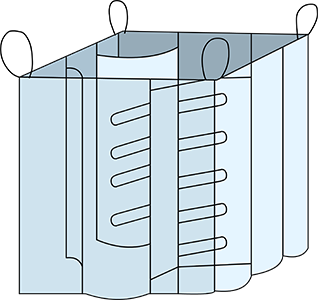

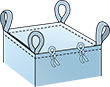

The Q bag design is constructed by sewing polypropylene baffles across the four corners of the FIBC bag. Thus, when the bag is filled, the baffles prevent the sides from bulging out or falling over when being stored or transported, giving the bags a straight shape.

Q Bags offer numerous benefits to the customers :

- Ability to fill 30% more material per bag as compared to the standard FIBC because of uniform material flow to all four corners.

- Reduced spillage and better usage and optimization of the available storage space.

- Improved stacking in the warehouse makes it look neater and improves overall aesthetical appeal.

- Remains within the Pallet dimensions when filled.

Baffle Bags find their application in the Food, Chemical and Pharmaceutical industries

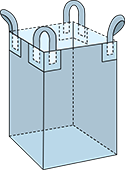

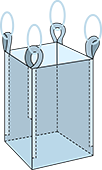

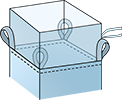

Cross - Corner Loops

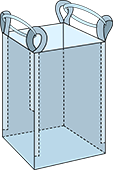

Side-Seam Loops

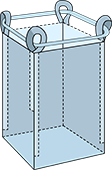

Sleeve Lift

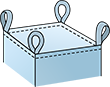

Hood Lift

Ancillary Loops

Double Stevedore Straps

Single Stevedore Strap

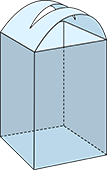

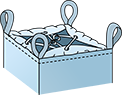

Open Top with Hem

Tie-Down Flap

Duffel Top

Open Top & Tightening Holes

Open Top with Draw Cord

Filling Spout

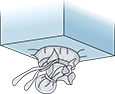

Discharge Spout

Discharge Spout with Iris Protection

Discharge Spout with Petal Closure

Discharge Spout with Sewn Cover

Discharge Spout with Protection Flap

Full Drop Bottom

Quick Discharge/ Conical base